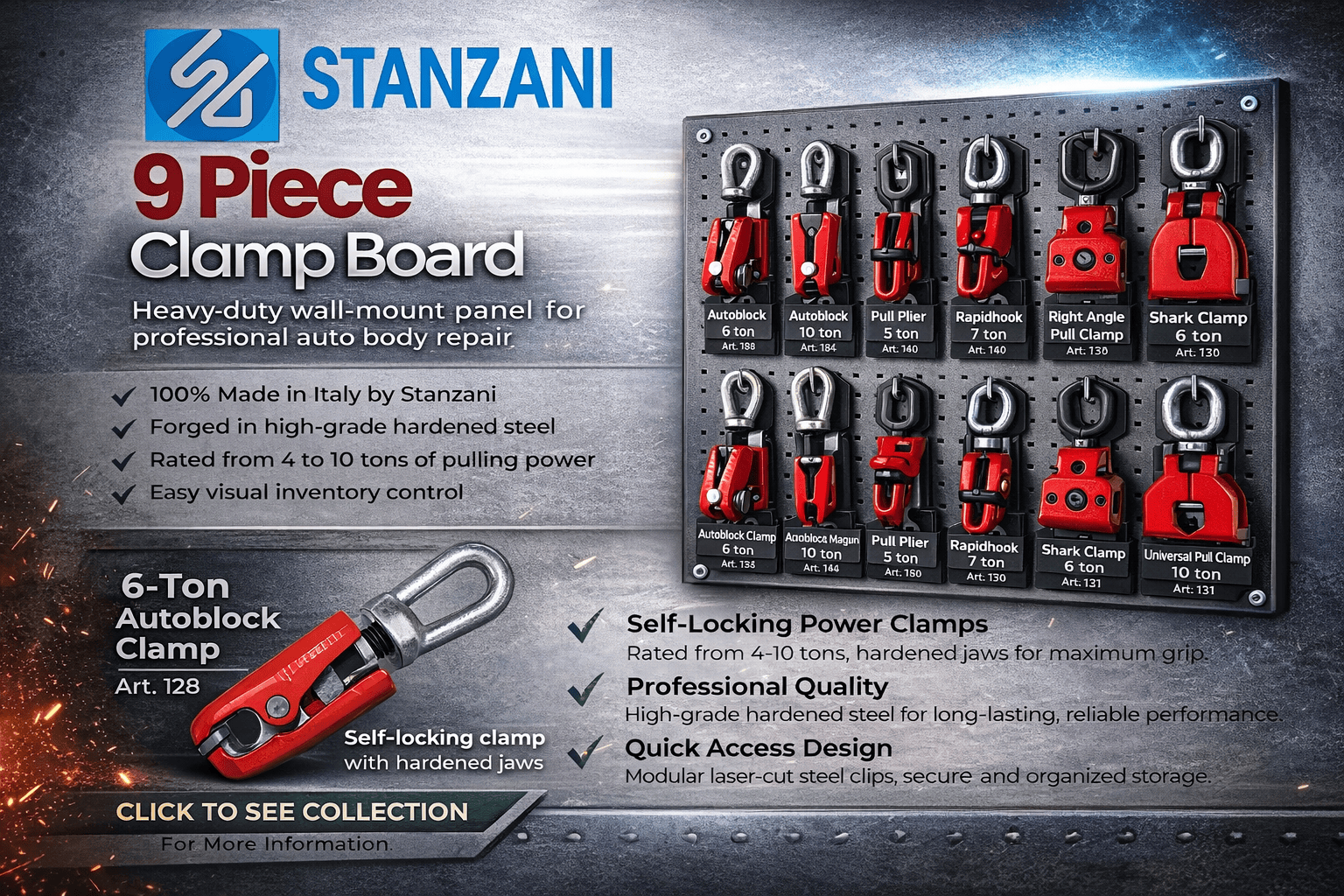

Modern Structural Pull Clamps for Today’s Vehicles

Modern Structural Pull Clamps for Today’s Vehicles

Modern Pull Clamps vs. Legacy Clamp Systems

Vehicle construction has changed dramatically over the past decades. Modern collision repairs demand controlled pulling, predictable load paths, and tools designed for today’s materials—not clamp systems originally developed for older vehicle designs.

| Stanzani Clamp Line | Traditional / Legacy Clamp Systems | |

|---|---|---|

| Design Philosophy | ✅ Engineered for modern vehicle construction, advanced steels, and OEM-driven repair procedures | — Originally designed decades ago for thicker steel and older vehicle platforms |

| Material Compatibility | ✅ Optimized for high-strength steels, aluminum, and mixed-material structures | — Limited adaptability to modern metallurgy and thinner panels |

| Grip Control | ✅ Controlled, predictable gripping designed to reduce slippage and panel damage | — Aggressive bite styles that may introduce variability depending on material |

| Load Path Management | ✅ Designed to support consistent force application during structural pulls | — Force application depends heavily on technician technique and setup |

| OEM Repair Alignment | ✅ Developed with modern OEM repair standards and documentation expectations in mind | — Predates many current OEM procedures and modern repair guidelines |

| Replaceable / Removable Teeth Serviceability & long-term grip performance

| ✅ Many higher-tonnage Stanzani clamps feature removable, replaceable teeth—so when wear happens, you restore bite performance without replacing the entire clamp. | — Teeth are typically non-serviceable. As bite surfaces wear, clamps may slip more often and usually require full replacement. |

| Risk Management | ✅ Helps shops reduce unnecessary risk when working on today’s vehicles | — May require additional caution when used on modern materials |

| Best Use Case | ✅ Modern collision repair shops focused on accuracy, consistency, and repeatability | — Familiar systems often used in legacy workflows |

| Verdict | ✅Built for modern repairs: predictable pulls, serviceable wear parts, and a clamp system aligned with today’s materials and shop expectations. | —Legacy approach: still familiar to some workflows, but often less optimized for modern materials, repeatability, and long-term serviceability. |

Comparison shown for educational purposes to highlight differences in design approach and application. Always follow OEM repair procedures and manufacturer recommendations.

Stanzani Clamp Line FAQ

Below are quick answers to common questions body shops ask when comparing modern pull clamps to older, legacy clamp systems. If you want help selecting the right clamp for a specific pull, contact our team—we’ll point you to the right tool for the job.

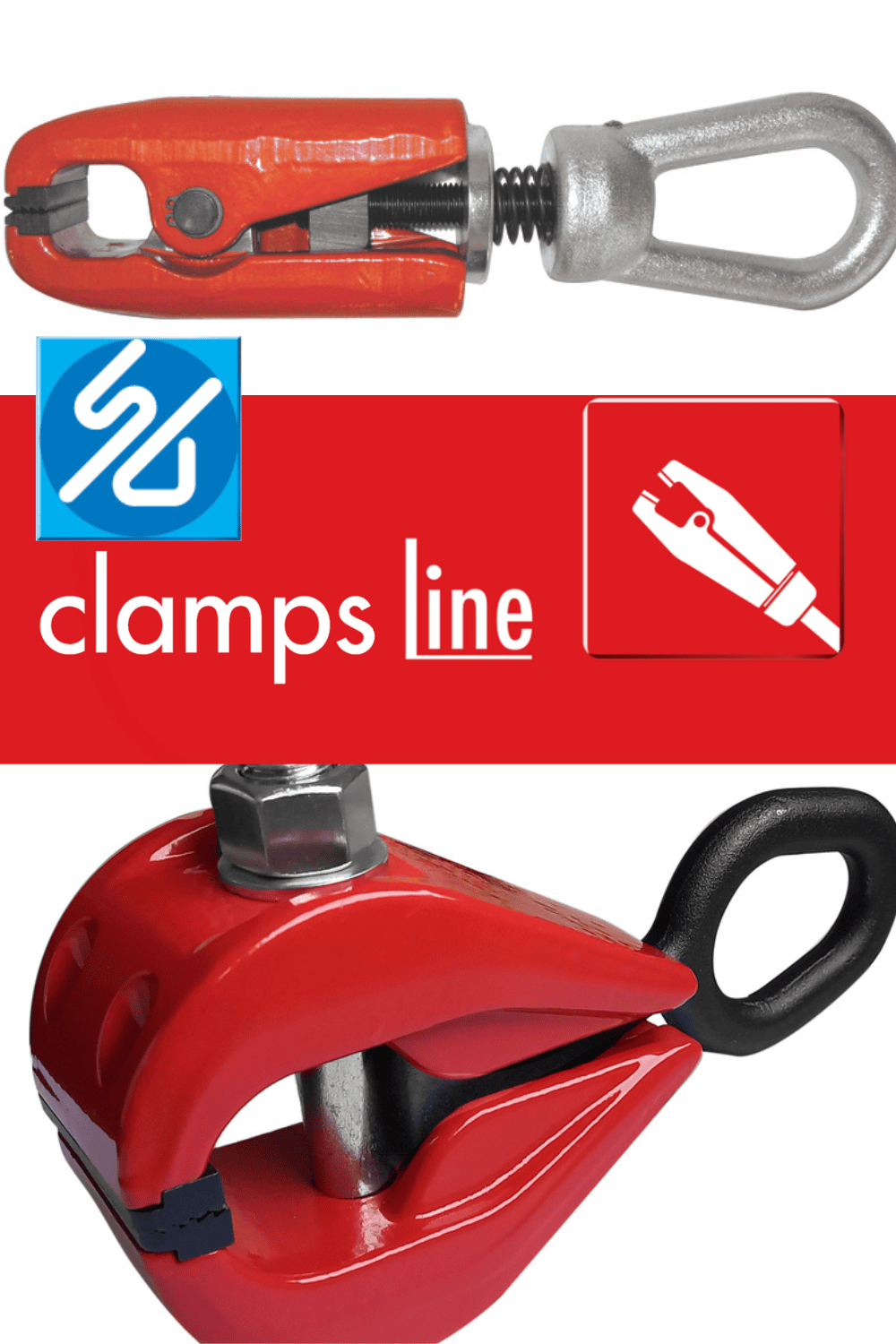

What makes the Stanzani clamp line different from traditional clamp systems?

Stanzani clamps are engineered for modern vehicle structures and today’s repair expectations—more consistent grip behavior, better control during pulls, and a clamp lineup designed around the realities of advanced steels, aluminum, and mixed-material construction.

|

Do Stanzani pull clamps work on high-strength steel vehicles?

Yes—many shops use Stanzani clamps specifically because modern repairs frequently involve HSS/UHSS. The right clamp choice and setup helps maintain controlled bite and predictable pulls. Always follow OEM procedures and use the appropriate clamp for the material and pull direction.

|

Which Stanzani clamps have replaceable teeth, and why does it matter?

Many of the higher-tonnage clamps feature removable, replaceable teeth. That matters because bite surfaces are wear items—when teeth wear, grip can degrade and slippage risk increases. With replaceable teeth, you can restore grip performance without replacing the entire clamp.

|

How do replaceable teeth help reduce clamp slippage over time?

Teeth wear is normal in real-world pulling. As a clamp’s bite surface rounds off, it may require more aggressive setup to hold, and slippage can become more likely. Replaceable teeth help you keep your clamps performing like they should—maintaining consistent bite and predictable holding power from pull to pull.

|

Are Stanzani clamps compatible with frame machines and bench systems?

Yes. Stanzani clamps are commonly used in structural repair environments where technicians need reliable holding power on frame machines and bench systems. If you tell us your setup and the type of pulls you perform most, we’ll recommend clamps that fit your workflow.

|

How do I choose the right clamp for the pull angle and tonnage needed?

Start with the repair objective: where you’re anchoring, the direction of pull, and the access you have. Clamp selection is typically driven by pull direction, available bite area, and required holding force. If you share a photo of the pull area or the repair plan, we can help you match the right clamp to the job.

|

Do modern clamp systems help reduce panel damage during pulling?

They can. Better control and consistent grip help reduce unintended movement, sudden slip events, and unnecessary rework. Proper clamp selection and setup supports predictable force application—especially important on today’s thinner panels and modern steels.

|

Do you stock replacement teeth and service parts?

Yes—depending on the clamp model. If you tell us which clamp you’re using (or the tonnage class), we can help identify the correct replacement teeth or service parts and keep your clamps performing at their best.

|

Can you help me build a clamp kit for structural pulls?

Absolutely. We can recommend a practical set of clamps based on the type of work you do most—rails, rockers, apron pulls, quarter pulls, and multi-angle structural pulls—so your shop has the right tools on hand when time matters.

|

Need help selecting the right clamp?

Tell us what you’re pulling (and what bench/frame system you’re using), and we’ll recommend the best Stanzani clamp options for your repair.

|