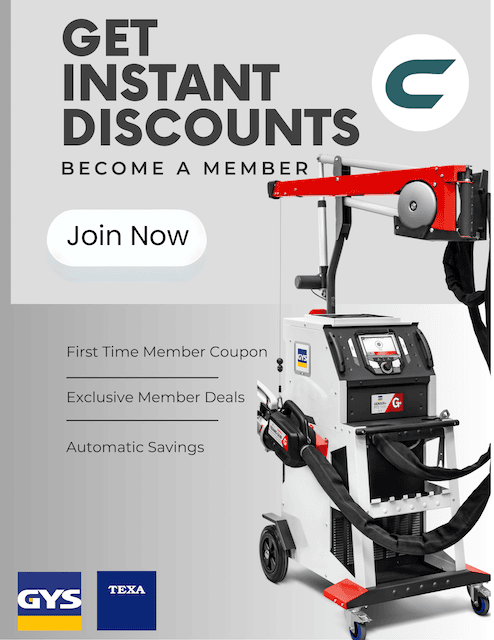

GYSpot Arc Pull 200

The GYSPOT ArcPull 200 is a high-performance drawn arc dent pulling solution designed specifically for aluminum panels. Engineered with advanced microprocessor controls and a patented Arc Pull gun, it allows for precise, efficient, and repeatable repairs while minimizing heat input and distortion. Unlike traditional capacitor discharge systems, the ArcPull 200 delivers a controlled drawn arc welding process—ideal for deeper pulls, structural panels, and OEM-approved aluminum repair standards.

Built for collision repair shops that demand accuracy and reliability, this system supports a wide range of studs and pull keys, ensuring flexibility across different repair scenarios. Its ergonomic design, simple interface, and robust power management make it an essential tool for technicians who want clean results, faster cycle times, and consistent panel integrity.

Choose Quantity

Key Product Details to Highlight

Process: Drawn arc stud welding for aluminum dent pulling – provides deeper penetration, stronger hold, and less surface contamination than capacitor discharge methods .

Stud Range: Supports Alu keys, washers, and M3–M8 studs, giving flexibility for a variety of dent repair scenarios .

Precision Control: Fully microprocessor-controlled with automatic regulation of arc time and current for consistent weld quality .

Clean Welding: Advanced current control minimizes oxidation and deformation, ensuring clean results even on high-strength or heat-sensitive aluminum panels .

Power Requirement: Runs on 220V single-phase, making it suitable for most body shop electrical setups .

Operator-Friendly: Features an ergonomic gun with quick-change chuck and an intuitive interface, reducing learning time for technicians .

Performance: Designed for deep dent pulls and structural panel corrections where maximum hold and strength are critical – a step up from CD-based systems .