OEM Approvals: Industry Progress or Profit-Driven Pitfall?

OEM Approvals: Industry Progress or Profit-Driven Pitfall?

In recent years, the collision repair industry has seen a growing trend among Original Equipment Manufacturers (OEMs) moving toward specification-based equipment approvals—and that’s a good thing. Instead of mandating a specific tool or brand, these OEMs are now approving equipment based on performance criteria, functionality, and technical compliance.

This shift empowers shop owners with choice, encourages fair competition, and promotes innovation among manufacturers who are challenged to meet or exceed defined standards. It’s a healthy move for our industry.

But not all OEMs are headed in that direction.

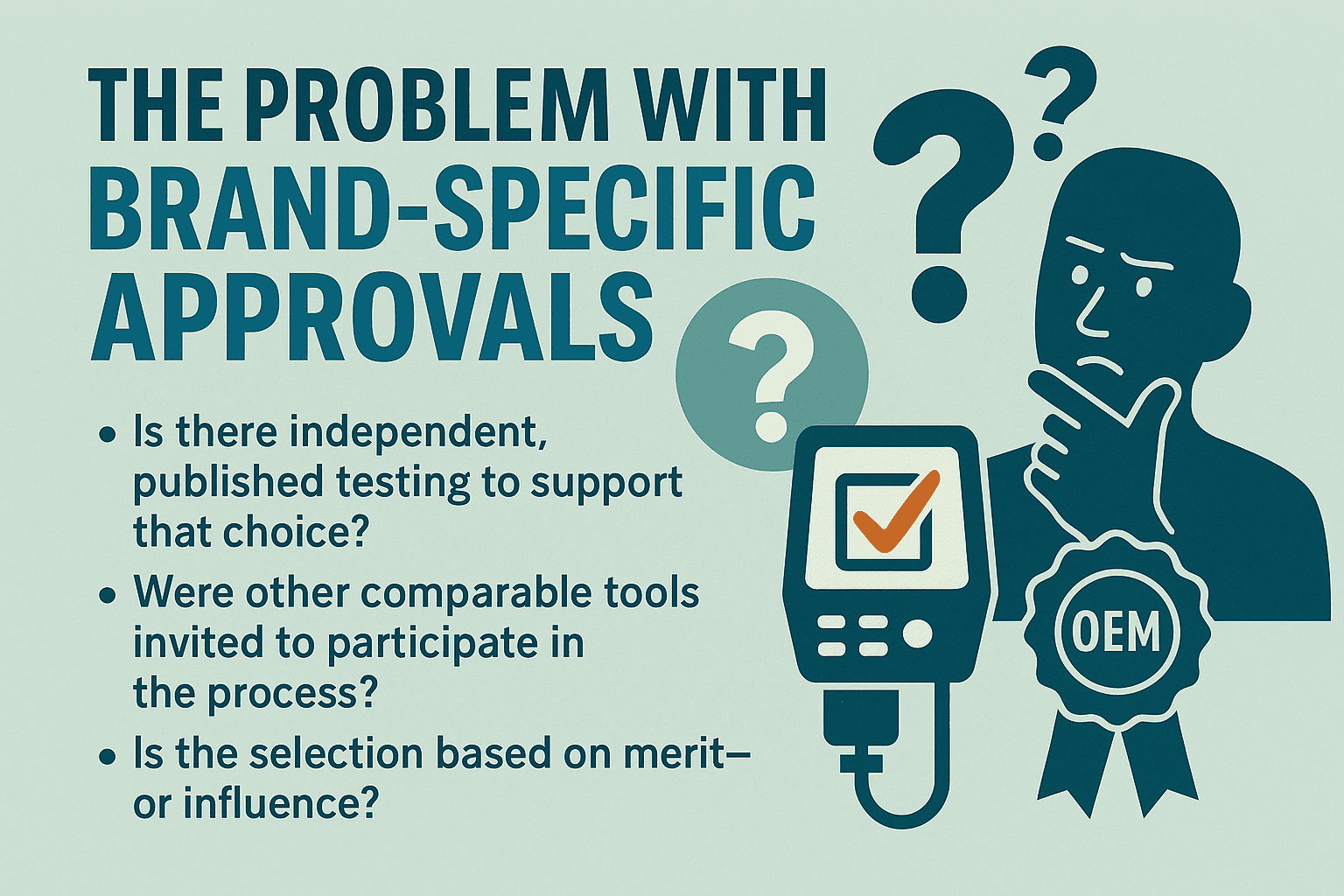

The Problem with Brand-Specific Approvals

Some OEMs continue to name one or two brands or products as the only acceptable tools for certification or compliance. That’s where problems begin. It raises a critical question:

Is the selected equipment genuinely the best option available—or is something else driving the decision?

When an OEM approves only certain products:

Too often, the answers are unclear. In fact, many in the industry quietly suspect that financial arrangements, exclusive deals, or internal brand favoritism may play a role in how these products get chosen.

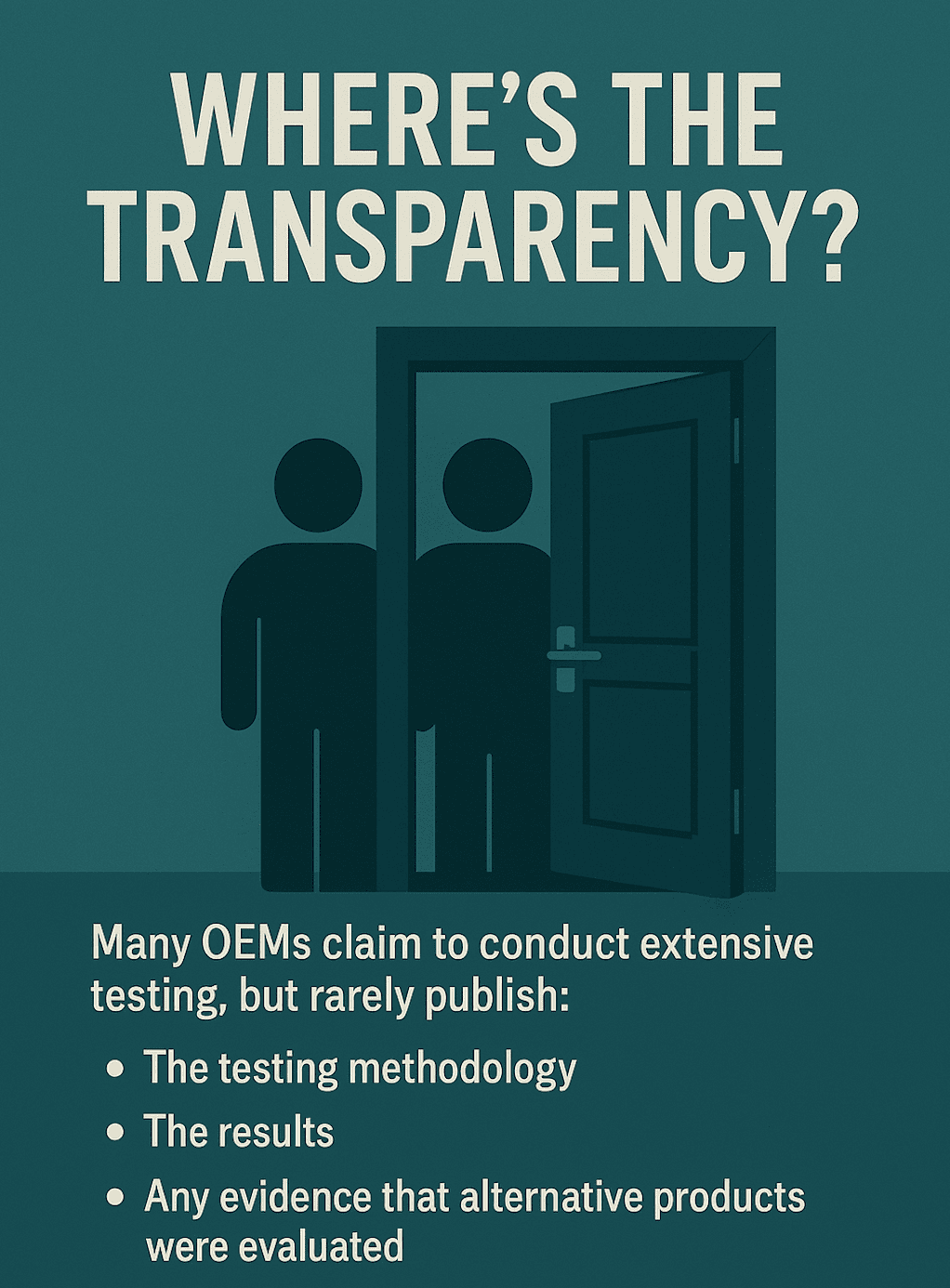

Where’s the Transparency?

Many OEMs claim to conduct extensive testing, but rarely publish:

- The testing methodology

- The results

- Any evidence that alternative products were evaluated

If these decisions are being made in closed-door environments without peer-reviewed data or third-party oversight, it’s fair to question whether the system is truly serving the end users—or just a few manufacturers and their corporate partners.

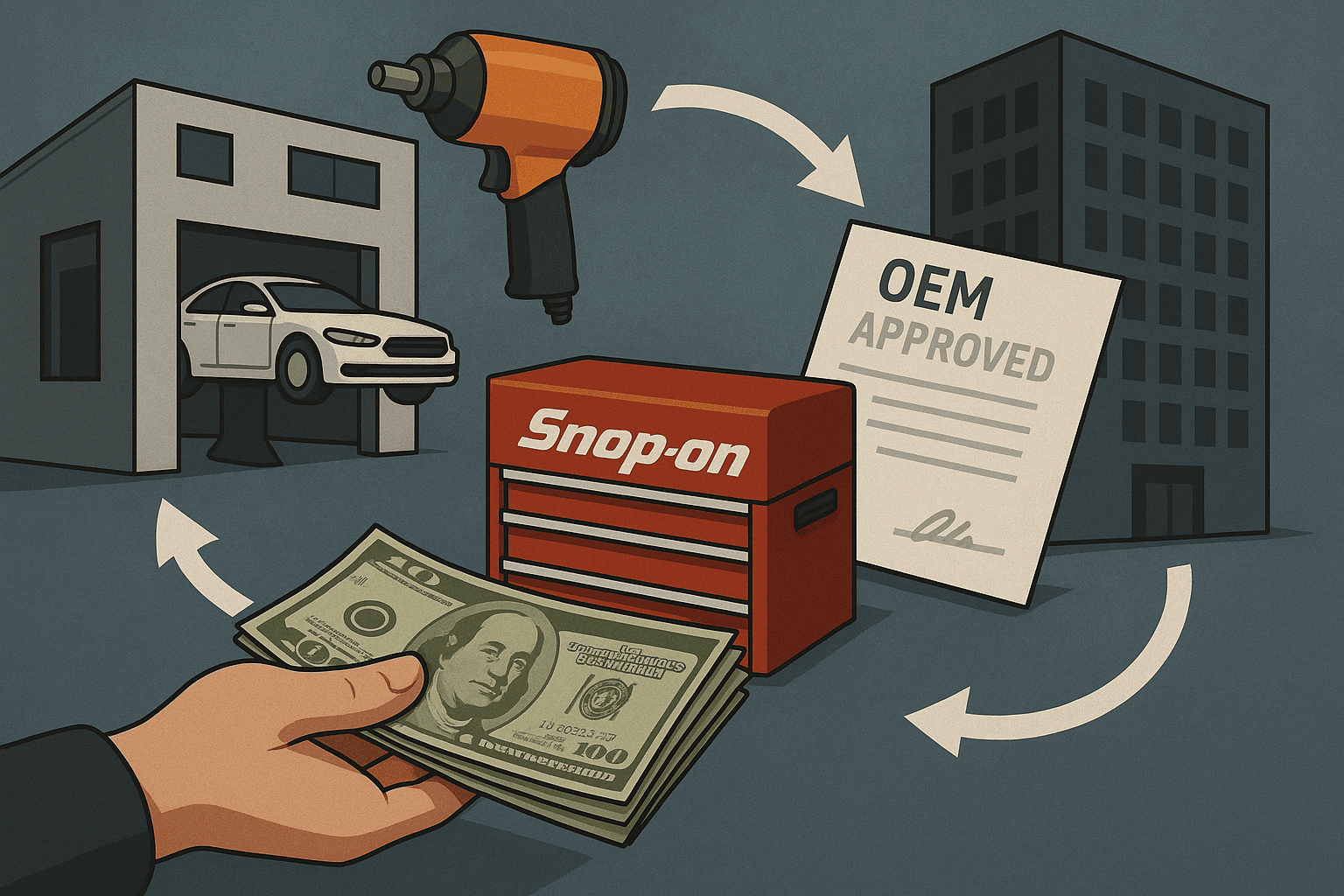

Snap-on: A Case Study in Conflicts of Interest?

Snap-on is a giant in our industry, and its reach extends far beyond tools. In fact, Snap-on not only owns multiple equipment manufacturing brands, but also operates divisions that administer OEM programs and provide financing for the very equipment it manufactures.

Think about that for a second.

- A collision shop is told they must buy Tool X to meet OEM requirements.

- Tool X is manufactured by a Snap-on-owned brand.

- The financing and ordering process is also to be managed through a Snap-on owned finance business.

That’s vertical integration at its most aggressive—and while it may be legal, is it ethical? Does it benefit the customer? Or does it limit options, inflate prices, and suppress better products from competing?

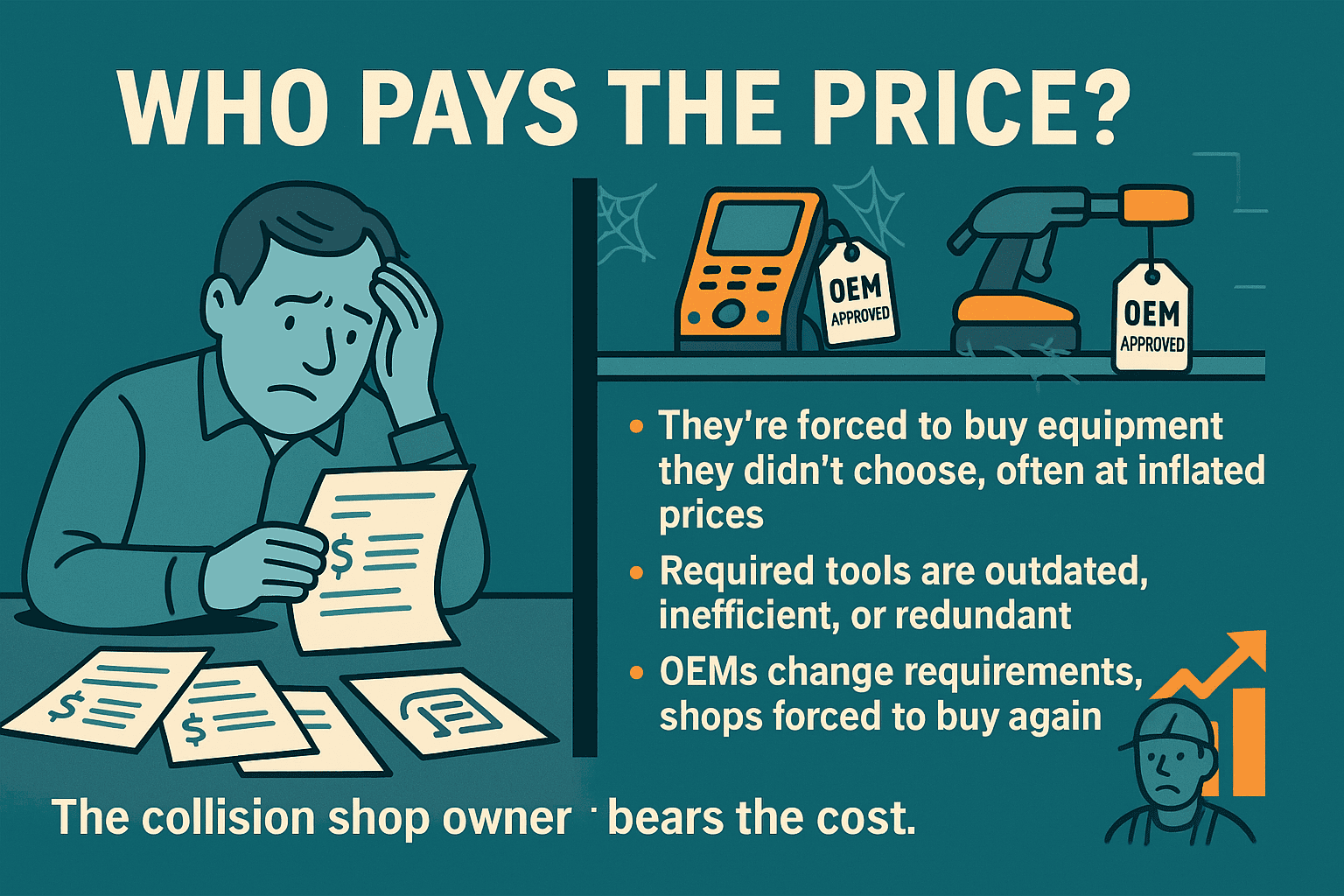

Who Pays the Price?

The biggest loser in all of this? The collision shop owner.

- They’re forced to buy equipment they didn’t choose, often at inflated prices.

- In many cases, the required tools are outdated, inefficient, or redundant.

- Technicians are left working around gear that collects dust or never lived up to expectations.

- When OEMs change requirements, shops are forced to buy again, adding even more cost and frustration.

This system, in its current state, too often punishes the shop while enriching the companies with the right connections.

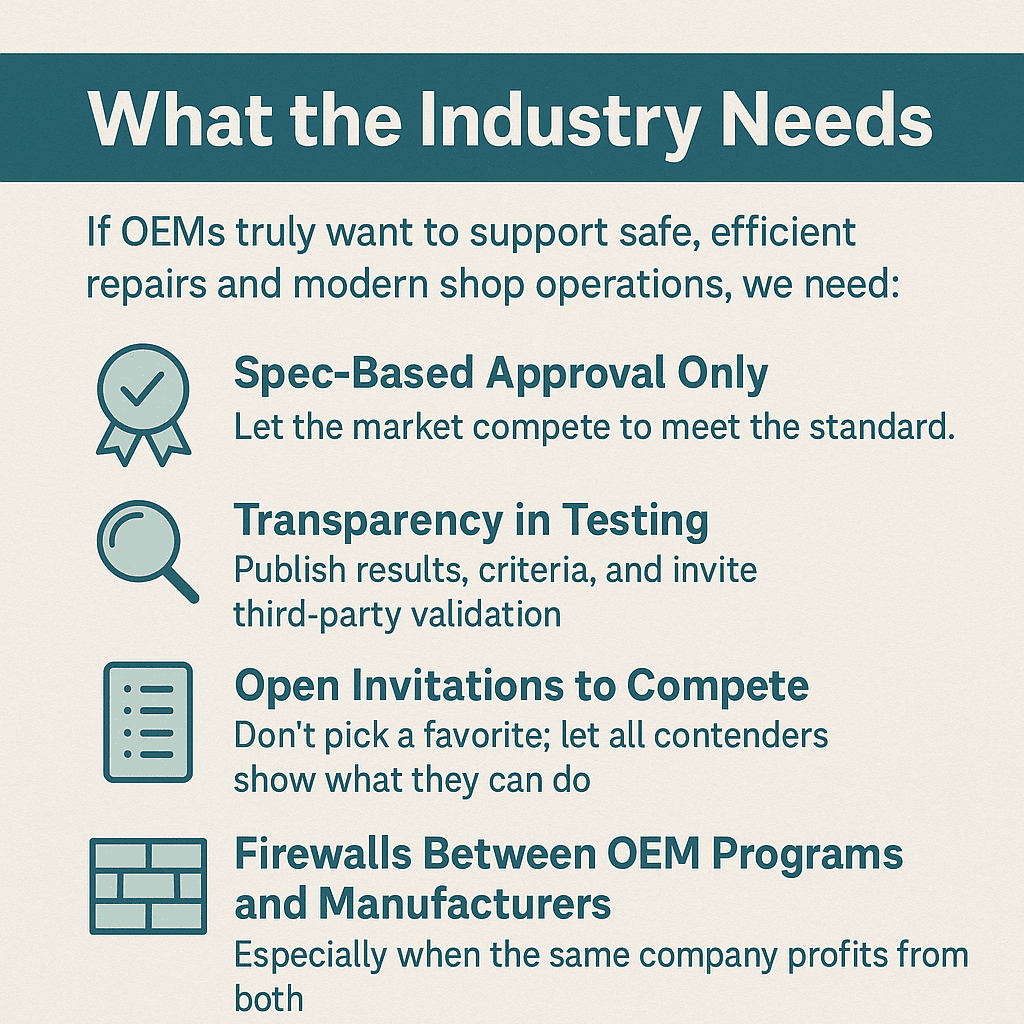

What the Industry Needs:

If OEMs truly want to support safe, efficient repairs and modern shop operations, we need:

- Spec-Based Approval Only – Let the market compete to meet the standard.

- Transparency in Testing – Publish results, criteria, and invite third-party validation.

- Open Invitations to Compete – Don’t pick a favorite; let all contenders show what they can do.

- Firewalls Between OEM Programs and Manufacturers – Especially when the same company profits from both.

This conversation isn’t about pushing one tool over another. It’s about fairness. It’s about ensuring that collision shops—who invest heavily in training, certification, and compliance—get the freedom to choose the best equipment for their needs without being boxed in by backroom deals or corporate entanglements.

The move toward spec-based approvals is a light in the dark. Let's keep pushing for transparency, competition, and accountability—not just because it’s good for business, but because it’s the right thing to do.

Browse GYS Equipment

Industry-leading spot welders, induction heaters, and repair solutions built for professional collision repair and OEM compliance.

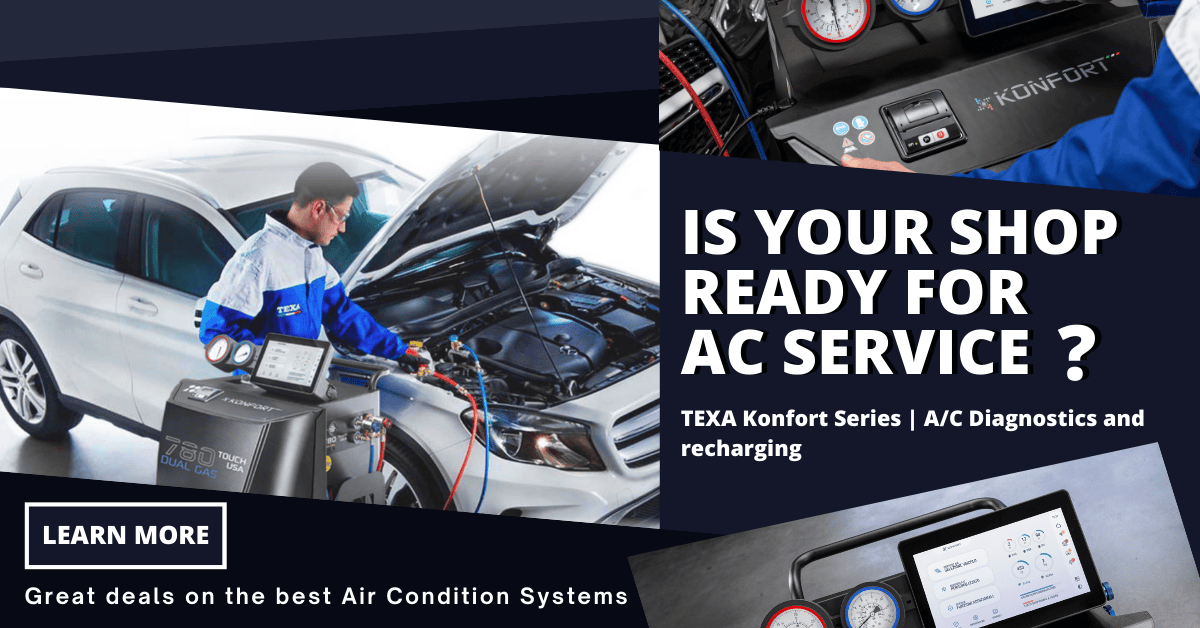

Explore TEXA Diagnostics

Powerful, multibrand diagnostic platforms for cars, trucks, motorcycles, marine, and off-highway vehicles—paired with cutting-edge software and rugged tablets.

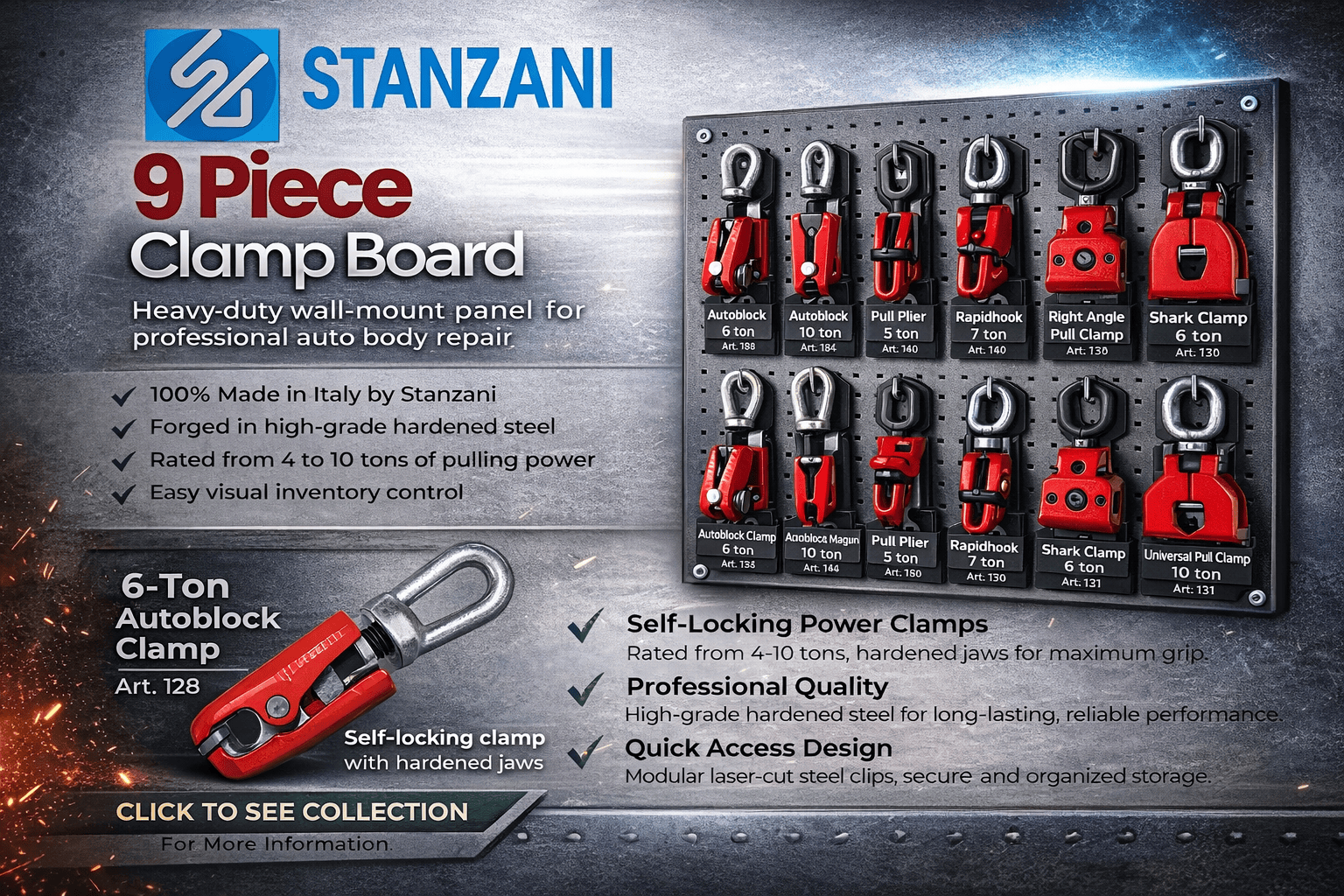

Shop Stanzani Clamping Systems

Engineered in Italy, Stanzani's precision clamping tools are trusted by top-tier shops for advanced structural repair and anchoring.

Now Live: Our New Website!

Now Live: Our New Website!

We’re excited to announce the official launch of www.innovativecrte.com! Our new site makes it easier than ever to explore our products, learn about the brands we represent, and request a quote. We’ll be continuously expanding with more resources, product support, and exclusive promotions.

Please Note: Our website is still under construction, but we’re proud of the progress and invite you to explore what’s live so far. If you come across any issues or have suggestions, please contact Nick Mattera at nick@innovativecrte.com. Nick is dedicating all available time to building new product pages and crafting an exceptional customer experience.

Your feedback is valued and will help shape the future of the site!